Magnesium Extrusion: Lightweight Metal for Advanced Applications

Magnesium is a lightweight metal known for its excellent mechanical properties, making it ideal for numerous industrial applications. Among the most efficient methods for shaping magnesium is extrusion technology, which transforms this versatile metal into precise, usable forms.

What is Magnesium Extrusion?

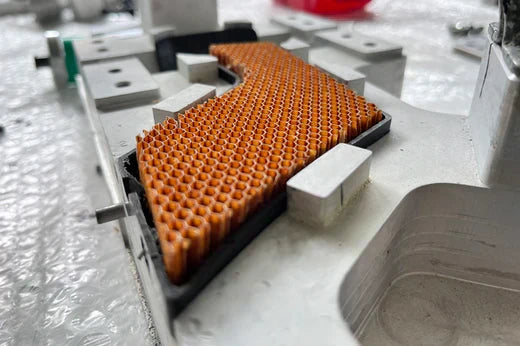

Extrusion is a process where magnesium alloys are pushed or drawn through a custom die to create objects with a fixed cross-sectional profile. This precision extrusion process is widely used for lightweight metals like magnesium and aluminum because it allows manufacturers to produce complex shapes, tight tolerances, and a smooth surface finish.

The Advantages of Magnesium Extrusion

- Lightweight and durable: Perfect for industries like automotive, aerospace, and electronics where reducing weight without compromising strength is critical.

- High precision: Enables the creation of intricate profiles for structural and functional components.

- Environmentally friendly: Magnesium is a recyclable material, aligning with sustainable manufacturing practices.

As extrusion technology advances, magnesium is set to play an even more significant role in modern manufacturing, offering innovative lightweight solutions to meet the demands of today’s fast-evolving industries.