Sheet Wrapping Technology

The Best Choice

Tube manufacturing is a crucial process in various industries, including aerospace and automotive. Among the technologies available for the production of composite tubes, Sheet Wrapping, Filament Winding and Pull Winding stand out. Each of these techniques has specific advantages and disadvantages in terms of performance and applications.

Sheet wrapping technology stands out for its ability to produce tubes with superior performance compared to traditional methods. Here are some of its main characteristics:

Material Efficiency: Tubes made with Sheet wrapping tend to have a significantly lower weight than those produced with other technologies. This translates into a material saving of up to 30% compared to Filament winding.

Stiffness and Performance: it can withstand higher loads before deforming or breaking under pressure.

Filament winding is a consolidated technique that offers several benefits, but also some limitations compared to Sheet wrapping in fact a tube in Filament winding can have a weight of 30% higher than one in Sheet wrapping. Pull winding is also a manufacturing method used, but the performance of tubes made with Sheet wrapping is superior even compared to this technology.

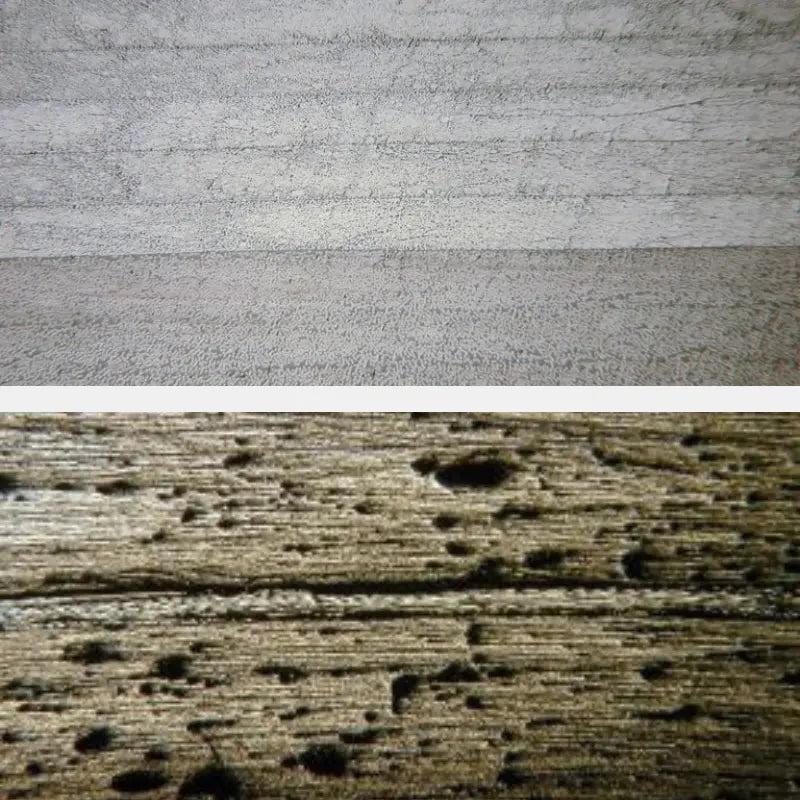

The image on the right shows the internal structure of the tube and the arrangement of the fibers, at the top Sheet Wrapping at the bottom Filament winding.

Production

Product designed and developed in Italy (watch video)

Shipping

Worldwide secure express shipping

Support

Monday-Friday

09:00-12:00 – 14:00-17:00

+39 0424 1958001

Register your product

Register your product and extend your warranty